DX52D Galvanized Coil | 1.0918 | 1.0350

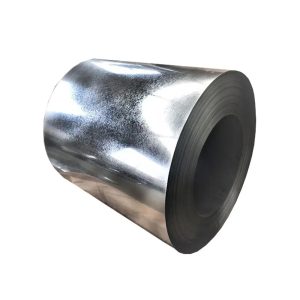

DX52D galvanized coil is a galvanized steel material with a thin and uniform zinc layer on its surface. This zinc layer can effectively protect the steel coil from corrosion and oxidation. In addition, DX52D galvanized coil also has good processing performance and welding performance, and can meet various building processing and construction needs. DX52D galvanized coil can be used for various welding operations. Since there is a layer of galvanized layer on its surface, you need to pay attention to the protection of the galvanized layer during welding to avoid welding defects.

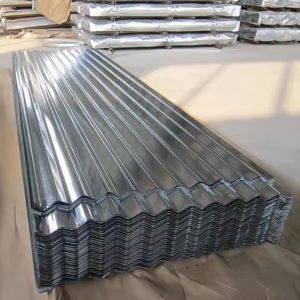

DX52D is a type of cold-rolled steel that is hot-dip galvanized for enhanced durability and protection. What distinguishes it is its unique blend of flexibility and durability. The steel is designed for applications that require deep drawing and shaping. It is ideal for complex parts like car body panels and roofing sheets. With a minimum yield strength of 220 MPa, it provides an ideal combination of bendability and durability.

- DX signifies that the steel is well-suited for deep drawing processes, allowing it to be easily molded into intricate shapes without compromising its strength.

- 52 refers to the minimum yield strength (in MPa) of the steel, which is approximately. 220 MPa.

- D indicates it is produced by hot-dip galvanization

Product Description

| Dimensions | Coils | Width: 600 – 1,250 mm (23.62″ – 49.21″) | |

| Thickness: 0.30 – 2.00 mm (0.012″ – 0.079″) | |||

| Coating Type | +Z,+ZF,+ZA,+ZM,+AZ | ||

| Coating Thickness | Z100 – Z250 g/m² | ||

| Surface | Big Spangle, Small Spangle, No Spangle | ||

Expert Advice on Choosing the Right Coating Type

Selecting the right coating type for DX52D Galvanized Steel depends on the environment and application. Here’s a quick guide:

- +Z (Standard Galvanized): Suitable for general applications with moderate corrosion exposure.

- +ZF (Zinc-Fe Alloy): Ideal for automotive and parts exposed to mechanical stress.

- +ZA (Zinc-Aluminum Alloy): Offers superior protection in harsh outdoor environments.

- +ZM (Zinc-Magnesium Alloy): Best for extreme weather conditions and heavy-duty applications.

- +AZ (Zinc-Aluminum-Magnesium Alloy): Provides maximum corrosion resistance for highly corrosive environments.

DX52D+ZM steel chemical composition % by mass max

| Grade | Material No. | C | Si | Mn | P | S | Ti |

| DX52D+ZM | 1.0350+ZM | 0.12 | 0.50 | 0.60 | 0.10 | 0.045 | 0.30 |

DX52D+ZM steel Mechanical properties

| Grade | Material No. | R90 min | N90 min |

Yield Strength MPa | Tensile strength MPa | Elongation A80 min |

| DX52D+ZM | 1.0350+ZM | – | – | 140-300 | 270-420 | 26 |

DX52D Galvanized Steel Applications

| Industry | Application | Properties |

| Automotive | Car body panels, exterior components, and structural parts | Strength, corrosion resistance |

| Construction | Roofing sheets, wall panels, and building frames | Durability, weather resistance |

| Home Appliances | Washing machines, refrigerators, and microwaves | Formability, rust resistance |

| Agricultural Equipment | Machinery parts, storage solutions | Strength, outdoor durability |

Application

Agricultural Modernization

Construction Engineering

Environmental Protection Engineering

Food Processing Industry

Intelligent Home Appliances

Medical and Health Field

New Energy Infrastructure