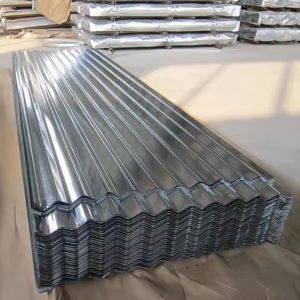

Galvanized Steel Strip

Designed for durability in harsh environments,galvanized steel stripscombine rust-proof zinc coatings with unmatched versatility. Whether you need electro-galvanized strips for electronics or hot-dip strips for outdoor construction, our products deliver consistent quality. Custom-cut lengths, slit edges, and temper options (soft/half-hard) ensure seamless integration into your manufacturing workflow.

Our galvanized steel strips are precision-crafted from high-grade cold-rolled steel, coated with a durable zinc layer (Z60 to Z275 coating weight) for superior corrosion resistance. Available in thicknesses of 0.15mm–3.0mm and widths of 10mm–600mm, these strips comply with ASTM A653, EN 10346, and JIS G3302 standards. Ideal for automotive components, cable trays, and HVAC systems, they offer excellent weldability and formability with a spangle-free finish.

Product Description

| Dimension | General hot – dip galvanized steel | Drawing hot – dip galvanized steel |

| Grades | DX51D+Z, DX51D+ZM, DX51D+AZ, DX51D+AM; CSA,CSB, CSC; SGCC | DX52D/DX53D/DX54D/DX56D/DX57D +Z/AZ/ZM; FS A, FS B, DDS, EDDS; SGCD1, SGCD2, SGCD3 |

| Grades reference | EN 10346; ASTM A653/A653M; JIS G 3302 | EN 10346; ASTM A653/A653M; JIS G 3302 |

| Standard | Q/ASB 385, Q/ASB 381, Q/ASB 386; Q/ASB 387 | Q/ASB 385, Q/ASB 381, Q/ASB 386; Q/ASB 387 |

| Thickness | 0.15 – 6 mm | 0.15 – 6 mm |

| Width | 600 – 1250mm | 600 – 1250mm |

| Scope of application | General use | Drawing deep, Deawing |

| Applicable industrials | Building, Home appliances, etc. | Building, Home appliances, etc. |

Common Surface Treatments

| Treatment | Features | Best For |

| Hot-Dip Galvanizing | Thick zinc layer (Z60–Z275), superior corrosion protection | Automotive parts, roofing, fencing |

| Electro-Galvanizing | Thin, uniform coating (5–20 µm), smooth surface | Electronics, appliances, fasteners |

| Galvannealed | Zinc-iron alloy layer, enhanced paint adhesion | Pre-painted panels, automotive bodies |

| Passivation | Chromate coating, added anti-white rust protection | Marine environments, coastal areas |

Why Choose Our Galvanized Steel Strips?

√Advanced Corrosion Protection

- Coating Options: Z60 (180 g/m²) to Z275 (275 g/m²) for indoor/outdoor use.

- Salt Spray Test: 500–1,500 hours (ASTM B117) based on coating weight.

√Precision Manufacturing

- Tolerance: Thickness ±0.02mm, width ±0.5mm (custom slitting available).

- Surface Finish: Regular spangle, minimized spangle, or smooth finish.

√Certified Quality

- Standards: ASTM A653, EN 10346, SGS RoHS compliance.

- Testing: Full MTRs (Mill Test Reports) with chemical and mechanical data.

√Fast & Flexible Service

- MOQ: 1 ton (volume discounts for 10+ tons).

- Delivery: 7–15 days for standard sizes; expedited options available.

Application

Agricultural Modernization

Construction Engineering

Environmental Protection Engineering

Food Processing Industry

Intelligent Home Appliances

Medical and Health Field

New Energy Infrastructure