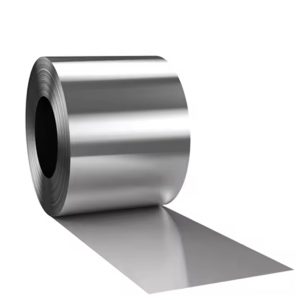

What Is an Aluminum Coil?

Aluminum coil is a continuous strip of aluminum sheet that is wound into a roll form. It is typically produced through hot rolling or cold rolling processes and widely used in automotive, construction, electronics, HVAC, packaging, and industrial manufacturing.

Available in different alloys, tempers, widths, and thicknesses, aluminum coils offer a lightweight, corrosion-resistant, formable, and conductive material for a wide array of applications.

Steel1stop supplies high-end Aluminum Coil. One-Stop Steel Service/Solution.

Available Alloys and Tempers

✅ Common Aluminum Coil Grades

| Grade | Properties | Applications |

|---|---|---|

| 1050 / 1060 / 1100 | Commercially pure, high conductivity, soft | Electrical, signage, chemical vessels |

| 3003 | Moderate strength, corrosion-resistant, good formability | Roofing, gutter, packaging |

| 5052 | High fatigue strength, excellent weldability | Marine, transport, fuel tanks |

| 5083 | Exceptional corrosion resistance | Marine, LNG tanks, structural |

| 6061 | High strength, heat-treatable | Aerospace, structural components |

| 8011 | Excellent for foil and packaging | Food packaging, insulation foil |

✅ Common Tempers

| Temper | Description |

|---|---|

| O | Annealed, softest state |

| H14 / H24 / H18 | Strain-hardened for strength |

| T6 / T651 | Heat-treated for high strength |

| H32 / H34 | Half hard / full hard for structural use |

✅ Technical Specifications of Aluminum Coil

| Parameter | Specification |

|---|---|

| Product Name | Aluminum Coil |

| Alloys Available | 1050, 1060, 1100, 3003, 3004, 3105, 5052, 5083, 6061, 8011 |

| Temper | O, H12, H14, H24, H32, H34, H18, T6 |

| Thickness Range | 0.2 mm – 6.0 mm |

| Width Range | 20 mm – 2000 mm |

| Coil Inner Diameter | 150 mm, 305 mm, 405 mm, 508 mm |

| Coil Weight | 500 kg – 5000 kg per coil |

| Surface Finish | Mill finish, Anodized, Embossed, Color coated, Polished |

| Standards | ASTM B209, EN 485, GB/T 3880, JIS H4000 |

| MOQ | 1 ton |

| Packaging | Eye to wall or eye to sky, wooden pallets, waterproof wrapping |

| Certificates | ISO 9001, SGS, BV, RoHS, Mill Test Certificate (MTC) |

Buy Aluminum Coil

Surface Treatment Options

| Finish | Description | Applications |

|---|---|---|

| Mill Finish | Natural rolled surface | General fabrication |

| Color Coated | Painted with polyester or PVDF coating | Roofing, cladding |

| Anodized | Electrochemically treated for corrosion resistance | Electronics, decoration |

| Embossed | Stucco, diamond, orange peel pattern | Insulation, building material |

| Mirror Polished | Highly reflective surface | Decorative, appliance panels |

Product Packaging

Adopting a professional industrial packaging solution that is moisture-proof and scratch resistant, each batch of steel is tied and fixed with customized wooden frames/steel strips, combined with anti rust coatings and cushioning pads to ensure zero damage during transportation. Clear product model, batch number, and storage identification on the outer packaging, supporting customized enterprise logos and information labels. Environmentally friendly and recyclable packaging materials practice green concepts, reducing transportation and disassembly costs.

Key Features of Aluminum Coils

✅ Lightweight – Weighs only one-third of steel

✅ Corrosion Resistance – Performs well in humid, chemical, and marine environments

✅ Excellent Formability – Can be stamped, bent, rolled, or deep-drawn

✅ Good Thermal and Electrical Conductivity – Ideal for heat exchangers and electronics

✅ Aesthetic Surface – Smooth and often anodized or color-coated

✅ Recyclable – 100% recyclable without loss of quality

Aluminum Coil Production Process

Casting – Molten aluminum is cast into slabs

Hot Rolling – The slab is hot rolled into coils of desired thickness

Cold Rolling – Further processed to refine thickness and improve strength

Annealing or Heat Treatment – To reach desired mechanical properties

Finishing – Surface treatments such as anodizing, coating, or embossing

Slitting & Packaging – Coils are cut to width, rewound, and packaged

Coil Weight Calculation Formula

To estimate the weight of an aluminum coil:

Weight (kg) = (Thickness mm × Width mm × Length mm × Density) / 1,000,000

Density of aluminum = 2.71 g/cm³

Aluminum Coil vs. Steel Coil

| Property | Aluminum Coil | Steel Coil |

|---|---|---|

| Weight | Lightweight (1/3 of steel) | Heavier |

| Corrosion Resistance | Excellent | Requires coating |

| Strength | Lower (unless alloyed) | Higher structural strength |

| Conductivity | Very good | Moderate |

| Cost | Higher (per kg) | Lower |

| Recyclability | 100% recyclable | Also recyclable |

Buying Guide: How to Choose the Right Aluminum Coil?

Define the Application – Is it for roofing, HVAC, packaging, or electronics?

Choose the Right Alloy – 3003 for roofing, 5052 for marine, 1060 for signage, etc.

Select the Thickness & Width – Based on equipment compatibility and usage

Decide on Surface Finish – Mill finish, embossed, color-coated, anodized?

Confirm Standards – Ensure compliance with ASTM, EN, or GB/T standards

Consider Coil ID & Packaging – Based on your processing equipment

Common Applications

Construction & Building Materials

Roofing and cladding

Gutters and downspouts

Ceiling panels and composite panels

Roller shutters and curtain walls

Automotive & Transportation

Heat shields

Trailer panels and truck bodies

Fuel tank covers

Reflective insulation

HVAC & Refrigeration

Fins for air conditioning units

Evaporators and condensers

Radiators and thermal insulation

Packaging Industry

Aluminum foil production

Food and pharmaceutical packaging

Beverage can lids and tabs

Quality Control and Testing

All coils undergo strict quality control, including:

✅ Chemical composition testing (Spectrometer)

✅ Mechanical property tests (Tensile, yield, elongation)

✅ Surface inspection for scratches, oil spots, and roll marks

✅ Thickness and width tolerance verification

✅ Coating adhesion (for color-coated coils)

Frequently Asked Questions (FAQs)

Q1: What is the difference between aluminum coil and aluminum sheet?

Aluminum coil is a continuous roll of sheet, while aluminum sheet is flat-cut to specific lengths. Coils are ideal for continuous processing or roll forming.

Q2: Can aluminum coil be used outdoors?

Yes, especially 5052, 3003, and anodized or color-coated coils offer excellent weather and corrosion resistance for outdoor applications.

Q3: What are common aluminum coil sizes?

Standard thickness: 0.2 mm to 6 mm

Widths: 100 mm to 2000 mm

Coil weights: 500 kg to 5000 kg

Q4: Can you slit the coil into strips?

Yes. We provide coil slitting services into custom widths, ideal for stamping, punching, or further forming.

Q5: Is there a minimum order quantity (MOQ)?

MOQ is generally 1 ton, but for stock items or sample orders, smaller quantities may be available.

Why Global Clients Choose Us?

Henan Gengfei Industrial Co., Ltd. is China’s leading supplier of steel and other metal products. Our company is dedicated to providing its customers with the quick quotes, superior quality products, competitive prices and fastest possible deliveries.

Direct Mill Partnerships

Long-term collaborations with leading steel mills secure preferential pricing on steel, ensuring up to 15% cost savings versus competitors.

Certified Quality

Strict adherence to ASTM, EN, and JIS standards, backed by mill test reports (MTRs) for every batch.

Dynamic Pricing

Real-time adjustments to market fluctuations (e.g., iron ore prices) guarantee fair quotes.

Dedicated Account Managers

24/7 technical and logistical assistance via email, WhatsApp, or WeChat.

Bulk Orders

5–10% discounts for 50+ ton purchases. Annual rebates up to 3% for repeat clients.

Dedicated Account Managers

Custom cutting, slitting, and coating services to match project-specific needs (e.g., ±0.1mm thickness tolerance).

Request an Appointment

Looking for a reliable supplier of aluminum bars in various shapes and alloys? Contact us for technical consultation, pricing, and delivery options. We provide OEM, bulk orders, and international shipping.